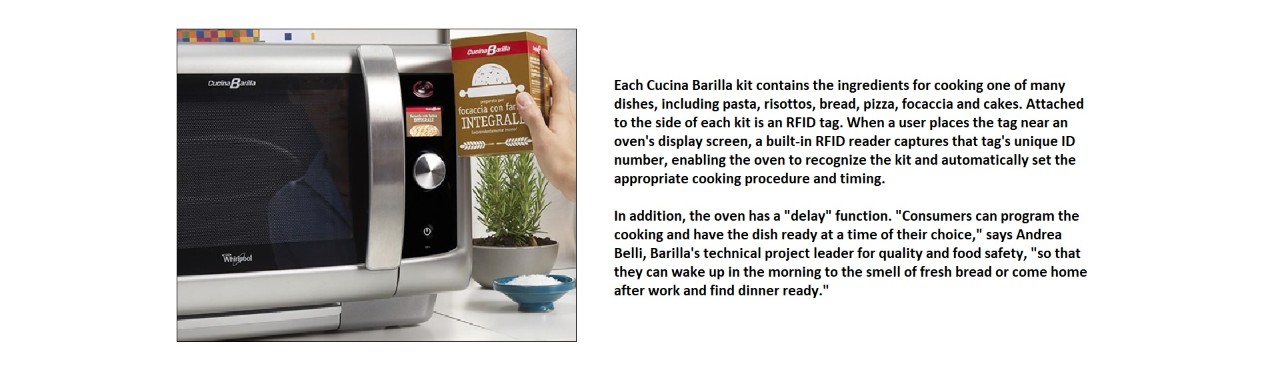

Each Cucina Barilla kit contains the ingredients for cooking one of many dishes, including pasta, risottos, bread, pizza, focaccia and cakes. Attached to the side of each kit is an RFID tag. When a user places the tag near an oven's display screen, a built-in RFID reader captures that tag's unique ID number, enabling the oven to recognize the kit and automatically set the appropriate cooking procedure and timing.

In addition, the oven has a "delay" function. "Consumers can program the cooking and have the dish ready at a time of their choice," says Andrea Belli, Barilla's technical project leader for quality and food safety, "so that they can wake up in the morning to the smell of fresh bread or come home after work and find dinner ready."

To automatically program the oven to make each recipe, as well as to display some manual instructions for a user, Barilla considered the use of linear or 2D bar codes, in addition to HF or ultrahigh-frequency (UHF) passive RFID tags. Barilla worked with the University of Parma RFID Lab, in conjunction with ID-Solutions, to determine which technology would be best for the solution, says Andrea Volpi, ID-Solutions' chief operating officer.

The group determined that for several reasons, 13.56 MHz HF RFID technology compliant with the ISO 15693 standard would be the best option, according to Francesco Fantoni Guerci, ID-Solutions' CEO. First, Barilla did not want to require that the ovens connect to the Internet, so the appliances needed to be able to access instructions for each recipe without having to retrieve them from a server. In addition, because the company intended to add new recipes over time, with the addition of new products, the oven needed to be able to receive new data with the use of each product. Barilla also wanted to ensure that each ingredient kit used to make a meal had a unique identifier that the oven would accept only once. After a kit was used to make a meal, the oven's reader would no longer recognize its tag's ID, thereby ensuring that consumers did not try to use that same tag multiple times but with their own ingredients. (This process could negatively impact the quality of what should be a Barilla product, he explains).

HF RFID provided these options, the company reports, since high-memory HF chips are available that can store a large amount of data. What's more, HF RFID readers were comparatively inexpensive to build into an oven.

ID-Solutions selected NXP Semiconductors' iCode SLIX chip with 1 kilobit of memory, and we designed a customized Smartrac Bullseye RFID tag and label that could be attached to the exterior of the product packaging. The firm encodes each label's tag with the appropriate recipe data, and then sends the labels to Barilla's manufacturing site, where they are applied to the packaging. ID-Solutions also designed a quality-control testing station – featuring an NXP reader chip and a reader antenna designed by ID-Solutions – with which Barilla reads a kit's tag before shipping that product to a customer.

The ovens also come with an HF reader chip and an antenna (customized by ID-Solutions) to interrogate a kit's tag when it is placed within short range of the oven.