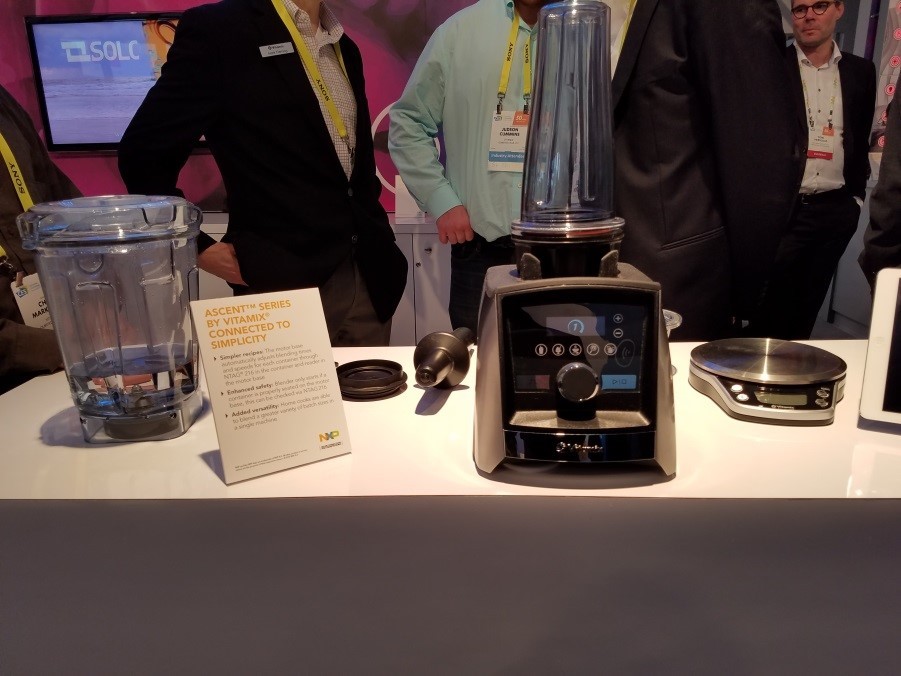

Product demo at NXP’s booth, CES 2017:

The full-sized Vitamix container (left-hand side); the tamping device for insertion into the full sized container; the model A250 blender with smoothie cup and blade base assembly attached; and the Bluetooth scale, which takes the container data from the tag via the Vitamix NFC reader built into the motor section, and translates into recipe proportions.

Benefiting from Smartrac’s can-do attitude

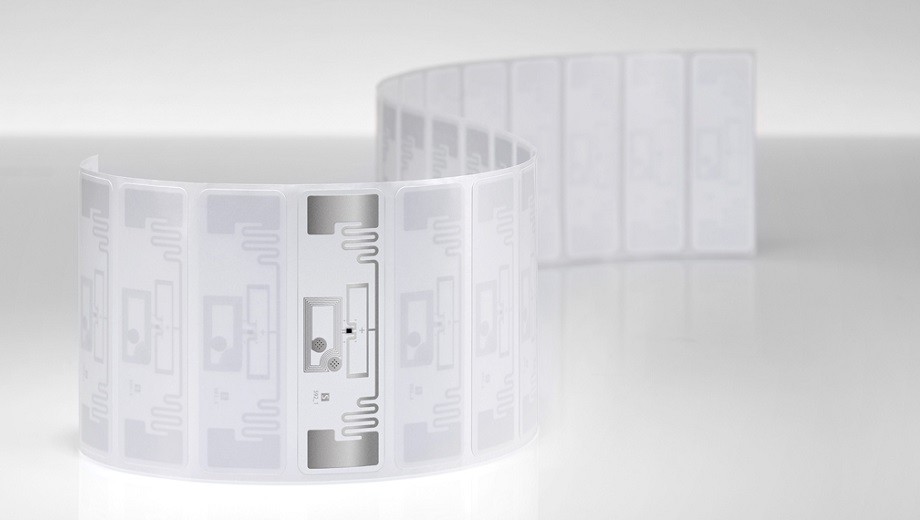

Once the NFC/reed switch-based interlock system was proven to work successfully in a test environment, another challenge arose: developing NFC tags that not only interact properly with the reed switches, but also can be molded in the container housings, plus survive the molding process, years of heat and vibration under use, and the thousands of brutal dishwasher cycles to come.

Smartrac passed that test to Kolar’s utmost satisfaction with its air coil NFC tags and – maybe even more important – with its overall “can do” approach. “When I was in Thailand for a family vacation, I had the chance to visit the Smartrac facility that manufactures the air coil transponders, the day before Christmas Eve. I thought I’d get a 10-minute tour, but they took me through all the production areas and gave me a lot of details. The product development team there was very supportive, and took this project under its wing immediately, almost as if it was a personal challenge. I knew then I was dealing with professionals, and that these were the guys we wanted to team up with,” Kolar remembers.

“Air coils can easily be made larger than standard NFC/HF inlays - in the Vitamix use case 81.25 mm diameter - which in this application affords a read range beyond what any standard inlays could provide. In fact, the air coil we’re using for Vitamix is the biggest coil we have ever made - a quite unique design and a perfect fit for their ring tag concept. From a design viewpoint, this freed up restrictions on the position and orientation of the NFC reader/antenna in the blender motor section. The reader/antenna could be moved to an easy-fit location away from the air-coil carrier within the container, further than a standard-range NFC/HF inlay would have permitted,” explains Art Barton, Sales Manager Americas Region at Smartrac.

Bright prospects – technologically and commercial

For Vitamix, the two NFC-enabled blender models and the supplied and separately sold containers and cups launched at the end of December 2016 are just a starting point, though a quite important one, as the company expects to sell more than a million units over the next three years.

“With our new products we are really elevating the culinary experience of our customers while complying with the strictest safety regulations of today and tomorrow,” Kolar says. “Furthermore, we have barely tapped into what’s possible with NFC. In the near future, there will not only be other blender models and containers with that technology, but also smartphone apps and all-new functionalities which take our customers’ experience to the next level. I’m sure Smartrac with its amazing willingness to take on new concepts and its attitude to say ‘yes, and…’ instead of ‘yes, but...’ will remain the perfect partner for Vitamix.”