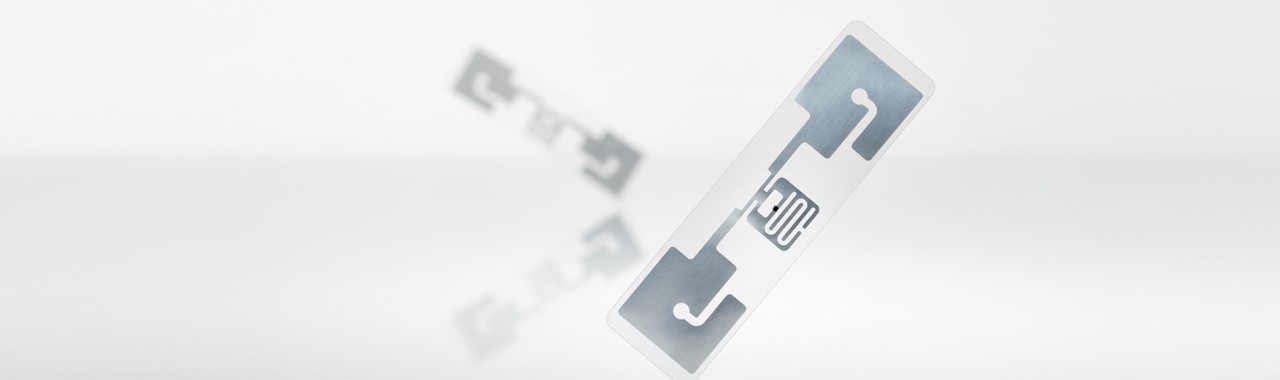

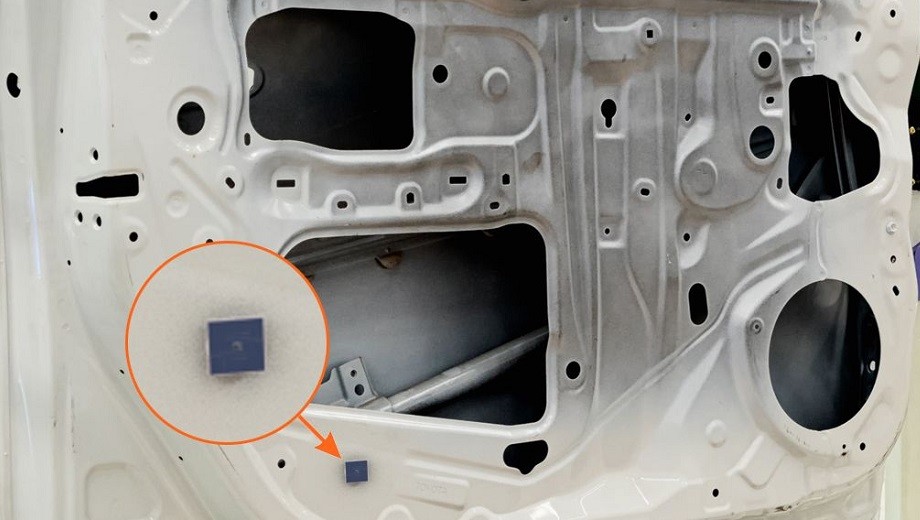

Driven by innovation and responsiveness to customer requirements, Smartrac has launched the new Sensor Dogbone™. It is designed primarily to measure moisture conditions in harsh industrial environments such as construction, energy, healthcare, automotive production and the military.

The first such sensor inlay on the market, Smartrac Sensor Dogbone is a passive UHF single-chip sensor solution that offers cost-efficiency, is easy to implement, and works on both low- and high-dielectric materials like cardboard, plastics, stone, wood and construction materials. It is deployable where active or semi-active sensors are not practical, and involves no battery maintenance, costs or problems with product lifetime or recycling.

Introducing new features to the company’s inlay and tag product range, this RFID sensor is based around a passive UHF inlay equipped with RFMicron’s Magnus(R)S IC. The inlay offers great performance, and accurately detects and measures moisture levels in the surrounding environment. The sensing information is digitized and wirelessly communicated to off-the-shelf readers using a standard UHF Gen 2 protocol READ command for further processing.

Advanced antenna design for better read range

Sensor Dogbone also features leading-edge antenna design. The antenna acts as a resistor/inductor/capacitor (RLC) tuned circuit. Any one of these, or any combination of the three, can be exploited to enable an antenna to sense its environment. The antenna converts environmental data into an impedance change, and then the sensor tag IC translates this into a sensor code, as it dynamically matches antenna impedance to die impedance.

Traditional sensors exploit changes in resistance to measure environmental variables, but this results in reduced tag read range due to power dissipated in the resistance. Sensor Dogbone’s ability to use inductance or capacitance means that read range issues can be avoided.

Virtually unlimited applications beyond moisture sensing

When configured as a moisture sensor, Sensor Dogbone measures the presence of water when the tag’s environment becomes wet. The interdigitated capacitor experiences a significant change in capacitance, when it changes from dry to wet; the dipole antenna registers an impedance change depending on the amount of water on the capacitor; and the sensor tag IC converts this into a code that indicates the amount of water present.

However, moisture sensing is only one potential application. The product’s application space is virtually unlimited, since any physical effect that affects capacitance, inductance, resistance or antenna loading can be exploited to produce a new, customized sensor tag to sense specific environmental conditions.